ASTRA Furnace Controller

The ASTRA Control System provides integrated control of all diffusion and LPCVD furnace system parameters. ASTRA is Ethernet-based using distributed control via a high-powered, tube-level microcomputer and intuitive, process-logical software.

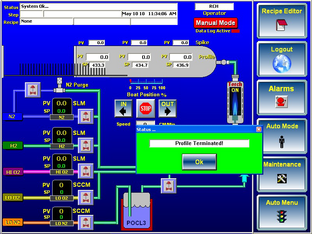

All ASTRA operations are accomplished through graphical and animated, touch screen access. Comprehensive data acquisition, logging and graphing provide real-time assessments for optimum process management

ASTRA Features

(Click feature for details)

-

Intel Core2Duo Processor.

DDRII RAM

High capacity hard drive.

Flash drive data transfer.

Printer module.

Microsoft Exel compatible.

-

Intuitive graphical touch interface

Fab-Friendly touch controls, even with gloves

-

Multiple control loops

Spike TC, profile TC or cascade control.

Auto profile or custom PID.

Programmable temperature tolerancing.

NIST offset program.

Data acquisition, logging and graphing.

0.1oC control resolution.

-

Multiple MFC control loops.

Programmable flow tolerance monitor and alerts.

Fault redirects with abort or branch.

Interface programming of peripheral components.

Comprehensive LPCVD vacuum control monitoring.

LPCVD auto leak-test protocol.

Hardware and firmware safety interlock

-

Intelligent motor control.

Programmable motion and feedback logic.

End-of-travel sensing with next-step function.

Over-travel sensing with fault redirects.

-

Universal Compatibility!

120/220/240VAC

50 or 60 Hz

Included UPS for loss of power failsafe

-

Operation and programming

Navigate.

Password management and access rights.

Recipe editing.

Temperature parameters.

Gas/fluid parameters.

Vacuum paramters.

Loading parameters.

Step times and event response editing.

Calibrations.

Alarm fault redirects.

Hardwire relay logic and firmware interlocks.

ASTRA Benefits

Precise control of temperature, gas and fluid flow, vacuum and loading parameters for optimum process performance and repeatability.

Intuitive programming and operation through graphical touch screen access for easy training and operation.

Tube-level microcomputer for high speed and masterful data management, which results in optimized yields and process tracking.

Distributed control with full safety interlocks for gas flow, vacuum, temperature and loading, which provide safe, reliable operation.

Optimized temperature control with divisible cascading and auto profiling to setup and maintain optimum temperature parameters.

User permissions protocols assure only qualified personnel can access programming, recipes and parameters.

Comprehensive alerts, alarms, redirects and monitors

for all parameters. Provides instant responses, reporting and recording of anything that affects process performance or safety.Full maintenance accessibility with integral trouble-

shooting and calibrations. Provides data for maintenance with no additional maintenance computer required.Advanced LPCVD control and monitoring functions for

sustained process repeatability.On-screen keyboard for easy data entry.

Lot tracking/run history for multiple lots per run. Allows recipe tracking of wafers and wafer lots.

Retrofitable to most any furnace brand or model. Modernizes all control attributes at low cost.

Optional ASTRA Host System. Provides centralized factory recipe management, downloading, data acquisition and logging for up to 99 tube-levels.

Controls Settings Screen

Data Log previous Process Run

Main Display with Alarm Notice